Notice: Function WP_Interactivity_API::_process_directives was called incorrectly. Interactivity directives failed to process in "" due to a missing "P" end tag. Please see Debugging in WordPress for more information. (This message was added in version 6.6.0.) in /home/eemepjwy/public_html/wp-includes/functions.php on line 6121

In order to maintain a cozy and healthy indoor climate, a home ventilation fan controller is essential. It enables homeowners to control the ventilation and airflow in their houses, which can provide a number of significant advantages:

1. Improve indoor air quality: Improved indoor air quality is a result of proper ventilation, which helps get rid of pollutants including dust, allergens, volatile organic compounds (VOCs), and odors. A ventilation fan controller ensures that fresh air is consistently circulated throughout the house by managing the fan speed and timing, reducing the concentration of pollutants and raising indoor air quality.

2. Moisture Control: Excessive moisture in the house can result in mold, mildew, and other moisture-related problems, which can be harmful to both the residents’ health and the building’s structural integrity. By regulating fan speed either automatically or manually in response to moisture levels, a ventilation fan controller enables homeowners to manage humidity levels effectively. This lessens the possibility of mold growth by preventing moisture buildup.

3. Energy Efficiency: Homeowners can reduce the amount of energy used by their ventilation system by using a ventilation fan controller. Energy consumption can be decreased when full ventilation capacity is not needed by regulating the fan speed according to the particular requirements of each room or area. Over time, this may lead to energy savings and decreased electricity costs.

4. Comfort and Temperature Control: A ventilation fan controller can help control the temperature and the general comfort of a home in addition to maintaining air quality. It can help distribute cold air from air conditioning systems or improve natural ventilation for cooling by altering the fan speed and airflow. The occupants’ living space is made more comfortable by this control over air flow.

5. Noise reduction: Some ventilation fans produce a lot of noise, especially when they’re operating quickly. When noise reduction is required, such as during sleeping hours or when engaging in activities that call for little background noise, homeowners can use a fan controller to lower the fan speed.

One option for ventilation fan systems is to purchase those equipped with a heat exchanger, which can recover heat from the air being extracted from the house. This method is highly efficient, but it comes with a higher cost and installation complexity. In contrast, we have introduced a straightforward fan system that utilizes a humidity sensing device to decrease the airflow rate when the indoor humidity levels are low. The fan control mechanism involves using a relay to switch the fan on and off.

Required Components

1x Arduino UNO Rev.03

1x USB-B Cable

1x 5V relay

1x Alphanumeric LCD (16 x 2 Characters)

1x TMP36

1x Diode: 1N4007

1x 9V DC Fan

1x 9V Battery

1x 9V Battery Snap

1x BC547

Buy these components on EEmentor Shop

Circuit Diagram

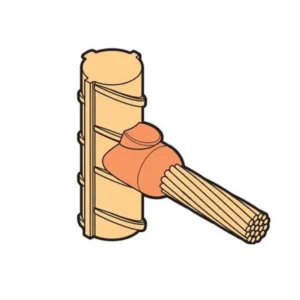

In this setup, we utilized an Arduino Uno as the primary control board. For visualizing the aperture, a 16×2 LCD display and an I2C module were employed. To measure the temperature, we incorporated a TMP36 temperature sensor. In order to regulate the Fan or motor based on temperature fluctuations, a 5V relay was included. To facilitate low-power switching of the relay, we utilized an NPN transistor, and a 1N4007 diode served as a free-wheeling diode of relay. For the opposite side of the relay, we employed a 9-volt battery to serve as the power supply, along with a 9-volt fan for showcasing or testing the prototype of the demonstration project. To limit the current, we integrated a resistor with a value of 4.7k/10k ohms.

Code

//https://www.eementor.co

//Libraries

#include <LiquidCrystal_I2C.h>

#include <Wire.h>

//Here, libraries are called

//Constants

#define TMP36 A0 //Define analog pin 0 of UNO for TMP36’s data pin.

#define Relay 7 //Define digital pin 7 of UNO for relay driving pin.

LiquidCrystal_I2C lcd(0x3F, 16, 2); //Define LCD type.

//Variables

float voltage, degreesC, degreesF;

void setup() {

Serial.begin(9600);

lcd.init(); // initializing the lcd

lcd.backlight();

lcd.setBacklight(HIGH);

}

//This is void setup, set the baud rate firstly. Then initialize the LCD and backlight.Then enter into void loop

void loop() {

voltage = getVoltage(TMP36);

// Now we'll convert the voltage to degrees Celsius.

// This formula comes from the temperature sensor datasheet:

degreesC = (voltage - 0.5) * 100.0;

// While we're at it, let's convert degrees Celsius to Fahrenheit.

// This is the classic C to F conversion formula:

degreesF = degreesC * (9.0 / 5.0) + 32.0;

Serial.print(" deg C: ");

Serial.println(degreesC);

// Serial.print(" deg F: ");

// Serial.println(degreesF);

lcd.setCursor(0, 0);

lcd.print("Temperature: ");

lcd.print(degreesC);

lcd.print((char)0xDF);

lcd.print("C");

if (degreesC > 24) {

digitalWrite(Relay, HIGH); // Turn the fan on

lcd.setCursor(0, 1);

lcd.print("Fan: ");

lcd.print("On");

} else {

digitalWrite(Relay, LOW); // Turn the fan off

lcd.setCursor(0, 1);

lcd.print("Fan: ");

lcd.print("Off");

}

delay(3000); // repeat once per 3min (change as you wish!)

//Set the cursor for Temperature printing on LCD and print it on 2nd row and from 1st column. Here, ‘lcd.print((char)0xDF);’ used to print Degree on the LCD.

lcd.clear();

//Delay for 3 second and clear the whole LCD

lcd.setCursor(0, 0);

lcd.print("www.EEmentor.co");

delay(2000);

lcd.clear();

}

float getVoltage(int pin) {

return (analogRead(pin) * 0.004882814);

}

Code Explanation

Here, libraries for LCD display called.

Here, initialize the pins of the relay driver and temperature sensor. Digital pin 7 is used for relay driving, and analog pin A0 is used as the temperature sensor output. Defined LCD type in the last line of these three lines.

Declared the variables here and float defines the fractional values here.

get Voltage function was created, which converts the analog value of sensors to the voltage outcome.

This is void setup. Here declared the baud rate and initialized the LCD credentials.

Entering the void loop. Voltage is calculated by calculating the TMP36 sensor’s output voltage and using different formulas to convert the detected voltage to degrees Celsius and degrees Fahrenheit.

Printing temperature to the serial monitor.

If a temperature is detected above 24 degrees Celsius, the fan will be on automatically; otherwise, it will remain off or get turned off.

The LCD will clear and print EEmentor’s logo for 2 seconds on the LCD.

In conclusion, a home ventilation fan controller gives homeowners control over their indoor environment, allowing them to optimize energy efficiency, maintain comfort, improve air quality, control moisture levels, and minimize noise. Homeowners can make their living area healthier, more comfortable, and more effective by making a premium fan controller investment.