Controlling the power supply in electronics is crucial as it helps safeguard electronic components from potential damage or destruction caused by exceeding their voltage and current limits. By regulating the power supply, you can ensure that these components receive the appropriate levels of voltage and current, effectively preventing failures or permanent harm. Stable and regulated power is also essential for proper functioning of electronic systems. Fluctuations or inconsistencies in the power supply can result in erratic behavior, malfunctions, or even system crashes. By maintaining stable voltage levels through power supply control, you can ensure reliable and consistent operation of the electronic system.

Efficient power management is of utmost importance in modern electronics to conserve energy and optimize performance. Through power supply control, you can implement techniques such as power gating, clock gating, and voltage scaling. These techniques minimize power consumption during idle or low-demand periods, thereby extending the battery life of portable devices and reducing overall energy usage.

Moreover, unregulated or poorly controlled power supplies can generate electromagnetic interference (EMI) that can negatively impact nearby electronic devices or disrupt communication signals. By implementing proper power supply filtering and regulation, you can mitigate EMI and ensure the reliable operation of other sensitive electronic systems in the vicinity.

Controlling the power supply is particularly critical in applications involving high-power or high-voltage systems to ensure user safety. Measures like overvoltage protection, current limiting, and short-circuit protection can be implemented through power supply control to prevent accidents, electrical shocks, or equipment damage.

Additionally, different electronic devices may have specific power requirements. By controlling the power supply, you can guarantee that each device receives the necessary voltage and current levels for proper functionality. This is especially important in applications where multiple devices or components need to be interconnected and operate together seamlessly.

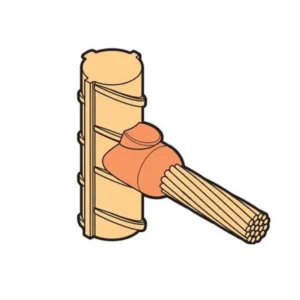

In this article, we will demonstrate the wiring of the IRF520 MOSFET Module Board, which is a convenient breakout board used to control higher loads. The MOSFET allows you to manage projects with higher voltages using a microcontroller. The MOSFET acts as a switch, separating the power from the main load. When the power is supplied to the MOSFET and it is closed, the power is transferred from one side to another. However, if the external power source is unavailable, your device can still draw power from the microcontroller.

Components

1x Arduino UNO Rev.03

1x USB-B Cable

1x IRF520 Mosfet

1x Solid Core Jumper Wires

1x 10k Potentiometer

1x Diode: 1N4007

1x 6V/9V DC Motor

1x 9V Battery

1x 9V Battery Snap

1x Breadboard 400 points

1x 1k Resistor

1x LED Red

Circuit Diagram

In the circuit diagram, we will utilize the MOSFET Module circuit. To control the desired device, you need to connect the power supply to the VIN and GND terminals. The POT is used here for the regulation of the power supply. LDE is used here for indication, and as a load, a DC motor is used. The system circuit incorporates a 1K pull-down resistor to ensure that the transistor remains in the off state during the microcontroller’s power-up phase and when the outputs are floating. The signal input, which is active HIGH, is connected to Arduino Digital Pin 6 and is typically used with 5V logic. However, it can be driven up to 10 volts to fully activate the IRF520 MOSFET. Although the IRF520 MOSFET is capable of handling up to 100 V at 9.7 A, this rating assumes a gate voltage of 10 V to ensure full activation with proper heat dissipation. Since the system is primarily designed for use with an Arduino or similar microcontroller, which can only drive 5V, the IRF520 will not be driven to full saturation, resulting in higher heat dissipation. A freewheeling diode was also used for the extra current protection.

Code

Download Link of ‘HCMotor.h’ Library - https://github.com/HobbyComponents/HCMotor

// http://eementor.local/

#include "HCMotor.h"

#define MOTOR_PIN 6

#define POT_PIN A0

HCMotor HCMotor;

void setup()

{

HCMotor.Init();

HCMotor.attach(0, DCMOTOR, MOTOR_PIN);

HCMotor.DutyCycle(0, 100);

}

void loop()

{

int Speed;

Speed = map(analogRead(POT_PIN), 0, 1024, 0, 100);

HCMotor.OnTime(0, Speed);

}

Code Explanation

Include HCMotor Code Library.

Assign to PWM/Digital Pin 6 and set the analog pin at A0 for the potentiometer.

Create an instance of the code library.

This is a void setup. Initializing the library: Attach the motor to digital pin 6. Set the duty cycle of the PWM Pulse with the modulation signal in 100uS increments to 100uS = 1mS cycle.

This loop is a void loop. Declared a variable Speed as an integer. Reading the A0 pin to determine the position of the pot and mapping the motor, which could be 0–1024, and reducing down to match the cycle range of 0–100 set the duty cycle to match the position.